Local: 908-757-3470

Flooring Adhesive

Flooring adhesive documents:

Click on the link to download the document

Affinity Series - 3000 Multi-Purpose Adhesive

3000 is designed for carpet in a direct glue down or double glue down application and installing fibrous felt back sheet flooring.

Affinity Series - 6000 Pressure Sensitive Adhesive

6000 is designed for the installation of dimensionally stable vinyl-backed carpet tiles and vinyl tile & vinyl plank in a releasable application.

Affinity Series 3000 - Multi-Purpose Adhesive Specifications

DESCRIPTION:

DESCRIPTION:

Affinity Series 3000 Better Multi-Purpose Adhesive is a quick grabbing adhesive designed for installing carpet in a direct glue down or double glue down application and installing fibrous felt back sheet flooring. It is recommended for the installation of the following carpet backings: Action-Bac, Sponge-Rubber, Latex Unitary, High Density Foam, Latex Foam, and the majority of carpet backings found in the market place today. Affinity Series 3000 IS NOT APPROVED FOR USE WITH CARPET WITH AXMINSTER BACKING (refer to Signature Series DS 902). It is not recommended for vinyl-backed carpet, cushion backed vinyl, urethane unitary backed carpet, outdoor applications or where excessive moisture or hydrostatic pressure is present.

While the adhesive is designed to meet the challenges of poorly ventilated areas, sufficient air exchanges are still required to ensure proper curing of any latex-based adhesive.

ffinity Series 3000 Better Adhesive, manufactured

by Royal, is LEED compliant and is also compliant with South Coast Air Quality Management District Rule 1168.

E.Q. 4.1: Low-Emitting Materials: Adhesives & Sealants

E.Q. 4.3: Low-Emitting Materials: Carpet Systems M.R. 5.1: Regional Materials: 10% Extracted, Processed & Manufactured Regionally

M.R. 5.2: Regional Materials: 20% Extracted, Processed & Manufactured Regionally

Affinity Series 3000 Better also qualifies for the Carpet & Rug Institutes Green Label Plus Program. This is a third party certification with the most stringent VOC regulations in the country. 100% of all Raw Materials used to manufacture this adhesive are Extracted, Processed and Manufactured Regionally.

*LEED points are based on all materials used on a project.

SUB-FLOOR PREPARATION:

Follow all manufacturer’s recommendations and industry standards regarding sub-floor preparation. Moisture tests are required on all concrete sub-floors regardless of grade level, if freshly poured or classified as an older slab. Moisture testing should be performed by ASTM F1869 Calcium Chloride Tests with moisture levels not to exceed five (5) pounds per Twenty-Four (24) hours per one thousand (1000) square feet or, ASTM F2170 In Situ Relative Humidity Test with moisture levels not to exceed eighty (80) percent. Additional information with regard to these tests and results can be obtained through My Way’s Technical Service Department.

INSTALLATION DIRECTIONS:

Subfloor must be clean, dry, smooth and free of any contamination, which may interfere with the adhesive bond. Seal all chalky, very porous floors with PARABOND® M-620.

Follow floor covering manufacturer’s recommendations regarding layout, cutting, seaming and maintenance.

While the adhesive is designed to meet the challenges of poorly ventilated areas, sufficient air exchanges are still required to ensure proper curing of any latex-based adhesive.

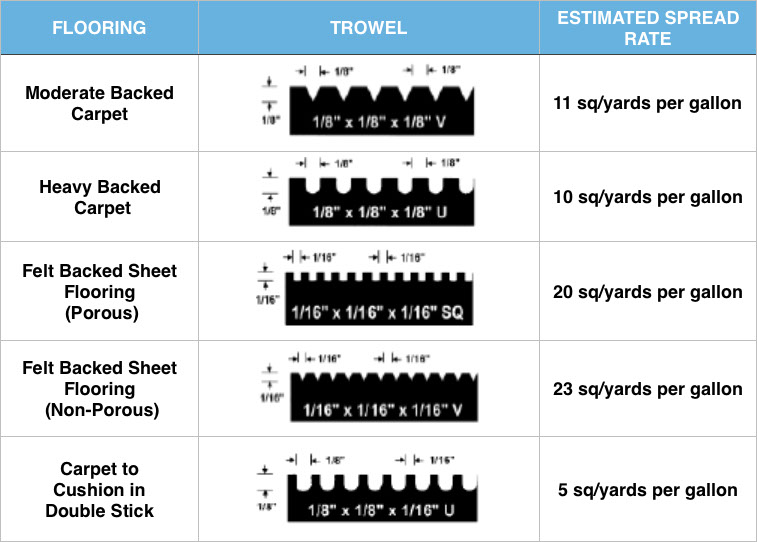

Spread adhesive with the recommended notched trowel leaving ridges of sufficient height to establish complete transfer to back of floor covering. Trowel sizes may need to be adjusted due to subfloor porosity, floor covering backing and open time requirements.

Lay most floor coverings into adhesive within 30 minutes. Lift floor covering periodically to check adhesive transfer to the backing. 100% adhesives transfer is required to promote maximum adhesive bond.

Roll carpet using the floor covering manufacturer’s recommended roller shortly after installation. Seams require seam sealing.

7. Follow the Carpet and Rug Institute Carpet Installation Standard 2009 where appropriate

RECOMMENDED SUBSTRATES:

Concrete

Portland Based Underlayments

Properly Prepared Gypsum

APA Approved Plywood

Terrazzo

Fiber Cement Underlayment

Radiant Heated Subfloors

Properly Prepared VCT (Single Layer)

Properly Prepared Sheet Vinyl (Single Layer, fully adhered)

RESTRICTIONS:

1. Do not use to install any vinyl or PVC flooring.

2. For Interior installations only.

3. Do not install over adhesive residue including cutback.

4. Do not install when MVER is over 5 lb’’s per 1,000 sf per 24 hours, per ASTM F1869.

5. Do not install when relative humidity is over 80%, per ASTM F 2170.

6. Do not use to install any vinyl or PVC flooring.

7. For Interior installations only.

8. Do not install over adhesive residue including cutback.

9. Do not install when MVER is over 5 lb’’s per 1,000 sf per 24 hours, per ASTM F1869.

10. Do not install when relative humidity is over 80%, per ASTM F 2170

11. Do not install when ambient temperature is not between 600F & 950F.

12. Do not install when ambient relative humidity is above 65%.

It is the sole responsibility of the installer to determine the suitability and compatibility of the adhesive for the

user’s intended use.

PACKAGING:

One -4 Gallon Pail

WARRANTY:

My Way Carpet Adhesives and Sealants offers a limited warranty for this product when used in accordance

with printed specifications. A copy of the limited warranty can be obtained by calling technical service at 877-466-9929 or visiting www.mywaycarpet.com/adhesive

CLEAN-UP:

Remove wet adhesive immediately with a damp cloth. Use Mineral Spirits. CAUTION: Mineral Spirits are flammable. Read and follow all precautions on container label.

Affinity Series 6000 - Pressure Sensitive Specifications

DESCRIPTION:

DESCRIPTION:

Affinity Series 6000 Pressure Sensitive is a premium acrylic emulsion, with excellent performance and environmentally friendly features. 6000 is releasable, non-flammable, non-hazardous and water resistant. It provides a strong, long lasting bond. 6000 is designed for the installation of dimensionally stable vinyl-backed carpet tiles and vinyl tile & vinyl plank in a releasable application. This adhesive can also be used to install cushion to recommended substrates in double glue down applications. Due to its pressure sensitive characteristics, 6000 eliminates concern about installing a non-porous backed floor covering over a non-porous substrate.

LEED CONRIBUTIONS:

E.Q. 4.1: Low-Emitting Materials: Adhesives & Sealants

E.Q. 4.3: Low-Emitting Materials: Carpet Systems M.R. 5.1: Regional Materials: 10% Extracted, Processed & Manufactured Regionally

M.R. 5.2: Regional Materials: 20% Extracted, Processed & Manufactured Regionally

*LEED points are based on all materials used on a project.

Affinity Series 6000 is Floor Score Certified and also qualifies for the Carpet & Rug Institutes Green Label Plus Program. This is a third party certification with the most stringent VOC regulations in the country.

SUBFLOOR PREPARATION:

6000 can be used over all grade levels of concrete in the absence of excessive moisture and alkalinity. Moisture tests are required on all concrete sub-floors regardless of grade level if the concrete is freshly poured or is classified as an older slab. Moisture testing should be performed by ASTM F1869 Calcium Chloride Tests with moisture levels not to exceed Five (5) pounds per Twenty-Four (24) hours per one thousand (1000) square feet or ASTM F2170 In Situ Relative Humidity Test with moisture levels not to exceed eighty (80) percent on existing slabs. New Construction Projects, or Green slabs can have a Moisture Vapor Emission Rate per ASTM F1869 of up to Eight (8) pounds per Twenty-Four (24) hours per one thousand (1000) square feet or 90% when tested in accordance with ASTM F-2170. Additional information with regard to these tests and results can be obtained through Royal’s Technical Service Department.

VINYL TILE/PLANK / CARPET TILE DIRECTIONS:

Refer to all manufacturers’ recommendations prior to installation to determine suitability of all materials to be used, approved substrates, sub-floor preparation, etc.

Subfloor must be clean, dry, smooth and free of any contamination, which may interfere with the adhesive bond.

Where subfloor is extremely porous, adhesive absorption may be in question, therefore it is recommended that the subfloor be primed with Parabond® M-620 Primer.

Refer to all floor-covering manufacturers’ recommendations regarding layout, cutting, seaming and maintenance.

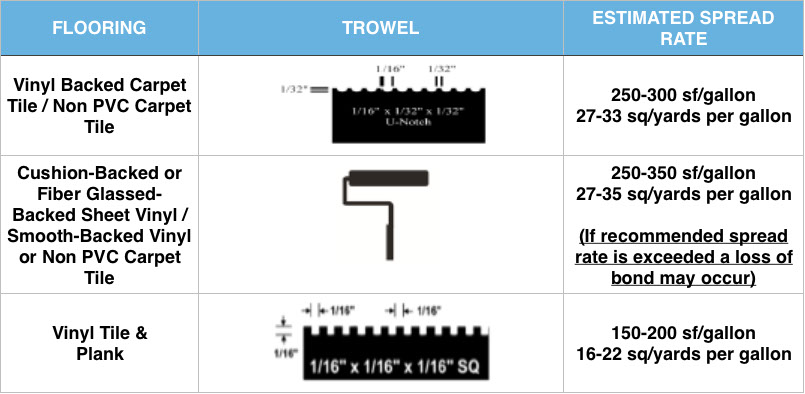

Spread adhesive using appropriate trowel (Rough or overly porous substrates could require the use of a 1/16” square notch trowel with tile or plank). Use the dry installation method in “tile over tile” applications and for situations requiring a releasable installation (carpet tile, double stick). If carpet tiles are installed “wet”, a permanent bond may result.

Roll floor covering as per manufacturers’ recommendations. Typical applications require rolling with a 100# 3-section roller in both directions immediately after flooring is placed.

Do not wet clean floor covering for a minimum of 14 days. This will allow the adhesive to properly cure.

Once adhesive turns clear, floor covering must be placed within 2-4 hours MAXIMUM with carpet tiles and within 2 hours for vinyl plank.

RECOMMENDED SUBSTRATES:

Concrete

Portland Based Underlayments

Properly Prepared Gypsum

APA Approved Plywood

Terrazzo

Fiber Cement Underlayment

Radiant Heated Subfloors

Properly Prepared VCT (Single Layer)

Properly Prepared Sheet Vinyl (Single Layer, fully adhered)

RESTRICTIONS:

1. Do not use to install any vinyl or PVC flooring.

2. For Interior installations only.

3. Do not install over adhesive residue including cutback.

4. Do not install when MVER is over 8 lb’’s per 1,000 sf per 24 hours, per ASTM F1869.

5. Do not install when relative humidity is over 80%, per ASTM F 1869.

6. Do not install when relative humidity is over 90%, per ASTM F2170.

6. Do not install when ambient temperature is not between 600F & 950F.

7. Do not install when ambient relative humidity is above 65%.

8. The dimensional stability of some vinyl flooring products is very sensitive to fluctuations in ambient environment conditions. My Way Carpet is not responsible for installation issues caused by dimensional changes in flooring.

9. It is the sole responsibility of the installer to determine the suitability and compatibility of the adhesive for the user’s intended use.

It is the sole responsibility of the installer to determine the suitability and compatibility of the adhesive for the

user’s intended use.

PACKAGING:

One -4 Gallon Pail

WARRANTY:

My Way Carpet Adhesives and Sealants offers a limited warranty for this product when used in accordance

with printed specifications. A copy of the limited warranty can be obtained by calling technical service at 877-466-9929 or visiting www.mywaycarpet.com/adhesive

CLEAN-UP:

Remove wet adhesive immediately with a damp cloth. Use Mineral Spirits. CAUTION: Mineral Spirits are flammable. Read and follow all precautions on container label.

CUSHION-BACKED VINYL / SMOOTH-BACKED CARPET TILE: For a releasable installation apply the adhesive to the substrate using a 3/8” short nap roller in a full spread installation (250-350 sf/gal spread rate). Do not apply adhesive in a perimeter installation. Allow the adhesive to set dry with no

Our Clients and As Seen In:

Please Refer Us To Your Friends And Family!!

Anso

Armstrong

Bruce

Beaulieu

Congoleum

Coronet

Formica

FERMA

Hagamen

Kraus

Mannington

Miliken

Mirage

Mohawk

Quick Step

Repellawood

Smart Strand

StainMaster

Wear Dated

Zickgraf

All of New Jersey:

Burlington County,

Essex County,

Hudson County,

Mercer County,

Monmouth County,

Ocean County,

Passaic County,

Salem County,

Sussex County,

Union County,

Warren County

All of Staten Island

Richmond County

In Pennsylvania:

Easton Area

ARTICLES

Use of this website signifies your agreement to our Terms of Service

and Privacy Policy © Copyright 2024 MyWayCarpet.com®

All rights reserved.